Every decision to promote biofuel production and utilization (i.e. subsidies), shall include all the supply chain elements to make sure that they are effective as the share of biofuels utilization is increasing.

We are honored to share a new article that is focused on the optimization of the supply chain for the production of biodiesel using forest residues as feedstock for methanol production.

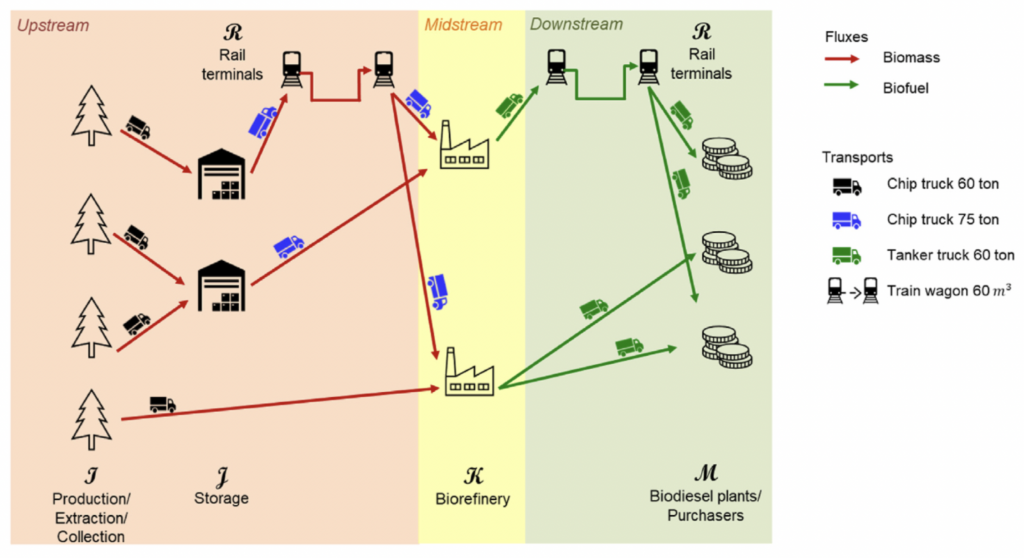

The optimization tool based on Mixed Integer Linear Programming (MILP) was adapted and applied to the Swedish case. This work illustrated the complexity of the supply chain for the production of the biofuels where all the steps can significantly affect the cost and efficiency of the conversion process. Particular attention is devoted to the characterization from economic and environmental point of view of the transport by truck and trains, the impact of the drying process as well as the size of the biorefinery plant.

F. Basile, L. Pilotti, M. Ugolini et al. Renewable Energy 196 (2022)

Results show that the forestry residues collection is limited by the size of the biodiesel plants. The calculated cost of the fuel is around 525 V/t being the biorefinery the major cost. The equivalent CO2 emissions are around 10.4 gCO2/MJMeOH thanks to the low carbon intensity of the Swedish electricity. A sensitivity analysis showed that the supply chain does not vary significantly assuming higher prices of biomethanol.

This work helps us to understand the complexity of the supply chain for the production of the biofuels where all the steps can significantly affect the conversion process cost and efficiency.